Complete solutions from a competent partner.

ATE Tools complete solution

ATE Tools GmbH is your system supplier for grinding tools and at the same time the complete solution for your production line. We connect and coordinate the services of different suppliers for you. You let everything be taken care of by a single source and receive an „all-round solution“ for your production facility: cutting, cylindrical grinding, finish-grinding, measuring, dressing, balancing and labelling. Last but not least, the filter system ensures that everything is spick and span. In close dialogue between you and our suppliers, we can offer you specific solutions that will aid you in your very particular competitive situation.

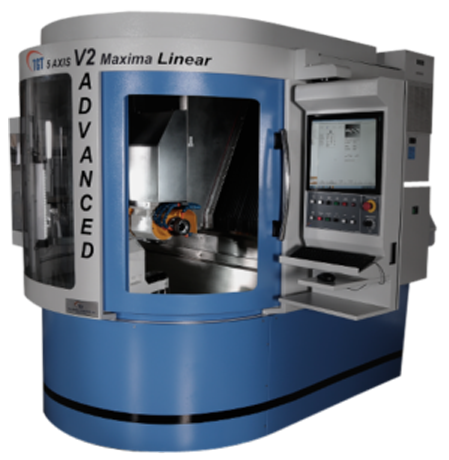

TGT V2 ADVANCED Maxima

V2 Advanced Maxima is a 5-axis, twin-spindle, high-precision tool grinding machine. High accuracy and excellent surface quality are its distinguishing features. Special tools can be used, and regrinding work is also possible without any problems. This machine is optimised for solid carbide tools with a grinding diameter of 1 mm to 32 mm.

TGT dressing technique

The TGT ACCUDRESS offers optimal dressing solutions. A cast iron frame provides a high degree of vibration damping and stiffness. The linear ball bearing allows free and effortless movement and absolute precision – for a perfect grinding result. Both the wheel head and the work head spindle are driven by a fixed-speed AC induction motor, ensuring that the TGT ACCUDRESS meets all the requirements placed on a grinding machine.

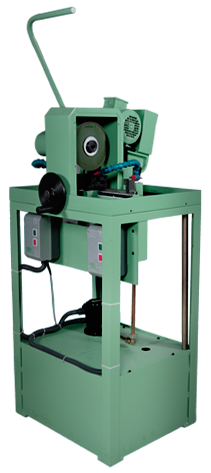

TGT separation technology

Simple separation of solid carbide rods by means of wet grinding. Thanks to the simple principle, the costs for cutting solid carbide rods can be kept very low.

Balancing technology

Efficiency and economy through a co-ordinated balancing system. With the precisely balanced grinding wheel, you can produce economically and with foresight. You will achieve a higher number of machined workpieces per grinding wheel; chatter marks and reduced surface quality are avoided.

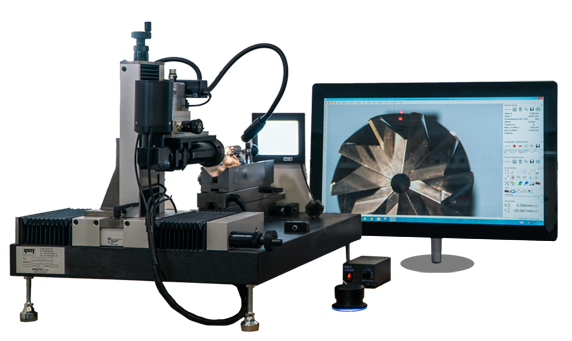

Measuring technology

Simple to operate, ergonomic design, high quality – all in one single measuring device. Incoming goods, tool repair, production and final inspection: the TC-210 offers the point of intersection for all this. A camera and a grid zoom lens are used to measure HSS, solid carbide, PCD and CBN tools. The fast and simple non-contact measurement makes it possible to achieve a perfect result for face geometries, peripheral geometries and the lengths of stepped ends.

Laser-marking technology

With the marking laser, metals, plastics and other materials can be marked in a contactless, permanent and flexible manner. The marking laser is easy to integrate, user-friendly and low-maintenance. The 10-Watt Mega-Light V40 marking laser is ideal for fast and professional laser marking of moderate unit quantities. Its 120 x 120 mm labelling area allows the marking of logos, graphics, texts, numbers, codes such as Data Matrixes and barcodes, consecutive numbering and printing in the round.

Filter system

Many sectors of the metalworking industry require high-purity cooling lubricants. Among other things, they are used to produce and regrind carbide tools. Our filter system is ideal for the ultra-fine filtration of low-viscosity machining oils. The filtered-out material can be disposed of in a transport container in a user-friendly way and is a sought-after reusable material.

Complete solutions for your production from a competent partner.

We strive to find customer-oriented solutions. Systematic original equipment or optimisation of existing production processes.

Your complete solution with just one contact person. Take advantage of your benefits.